|

11 March 2011 Author: Giorgos Lazaridis My Job - Repairing a NUM controller on a BIMA CNC center

BIMA 300 CNC Center BIMA 300 CNC CenterThe reason that i like my job, is because it never gets boring. Well, frankly speaking, it gets boring sometimes, but usually there is always something new to discover. I am a CNC technician, and luckily, i work with companies like IMA, Weinig, Schelling, which all have only high-end technology. I decided to upload some of my work because first of all, i think that it will be interesting for people who own such machines, and second it could be my future CV :D. I am not going to post EVERYTHING i do for it has no sense, only the problems that i enjoyed solving.

Service Report

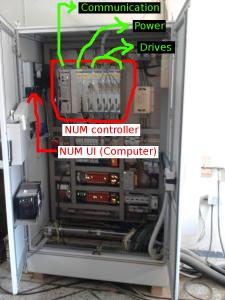

My colleague in front of the electrical cabinet My colleague in front of the electrical cabinet

Machine type: CNC stationary center

Brand/Type: IMA BIMA 300

Problem description

The customer reported that, sometimes, when he presses the power button to activate the machine, the NUM controller fails. Whenever this happens, he gets no error message in the computer (UI) screen. The LEDs on the NUM communication module do not indicate a problem, but the "Serial Link Fault" LED on the power module and the axis drives are turned on.

My experience tells me that, the word "sometimes" will give us a hard time. And this is normal, because if something is destroyed, then the problem appears all the time, and with a quick reverse engineering the problem can be easily found. But if the problem appears and disappears, this is the worst case scenario. We visited the customer many times, but the problem did not appear. Until finally, he called us and told us that this very morning, he was unable to turn on the machine, no matter how hard he tries.

This is what we faced when we went to the customer (click to enlarge):

|

|

| The red LEDs are the "Serial Link Fault" |

This is the topology of the electrical cabinet, regarding the NUM controller |

Normally, we started by checking all the wires on the NUM. We took out each and every wire, cleaned it with spray and plugged it in again. But the problem still occurred. Then i tried to reproduce the error, by removing wires while the CNC was in operation. I did this for all wires. Whenever a wire was unplugged, the system was forced to fail, but every time we got different error messages on the UI. Remember that the problem that the machine has, did not send an error on the UI. So this is not a wire problem.

Then, we took out the first module of the NUM (which is responsible for the communication and has also the CPU), to see what' going inside and cleaned it with dry air. There is a trick to the whole operation: There is a rechargeable battery 3.6V, which is used to maintain the system parameters of the machine, whenever the controller is not on power. This battery must NOT be unplugged from the motherboard no matter what, because if it does, all parameters will be lost, and it is not fun passing the parameters again.

|

|

|

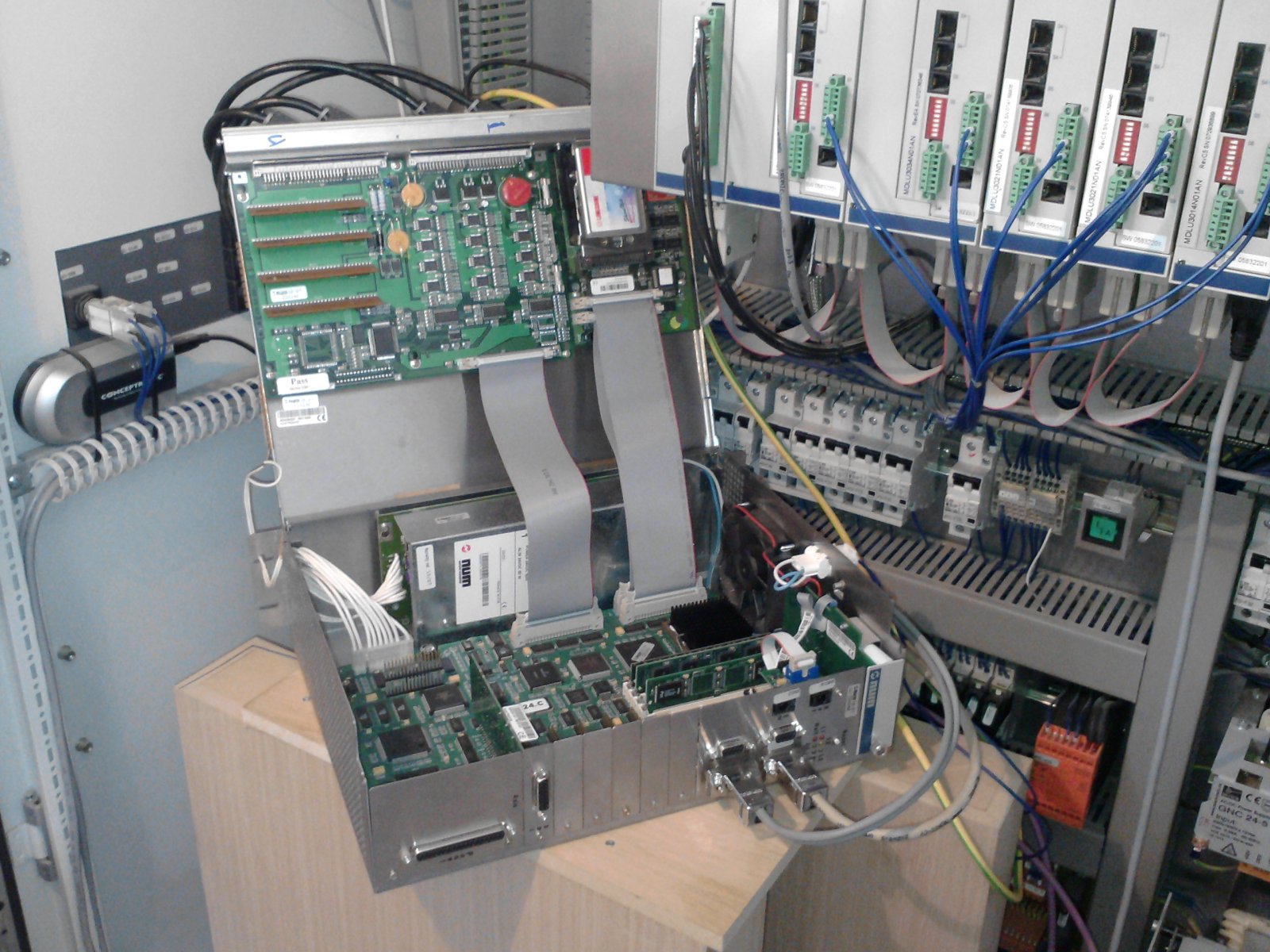

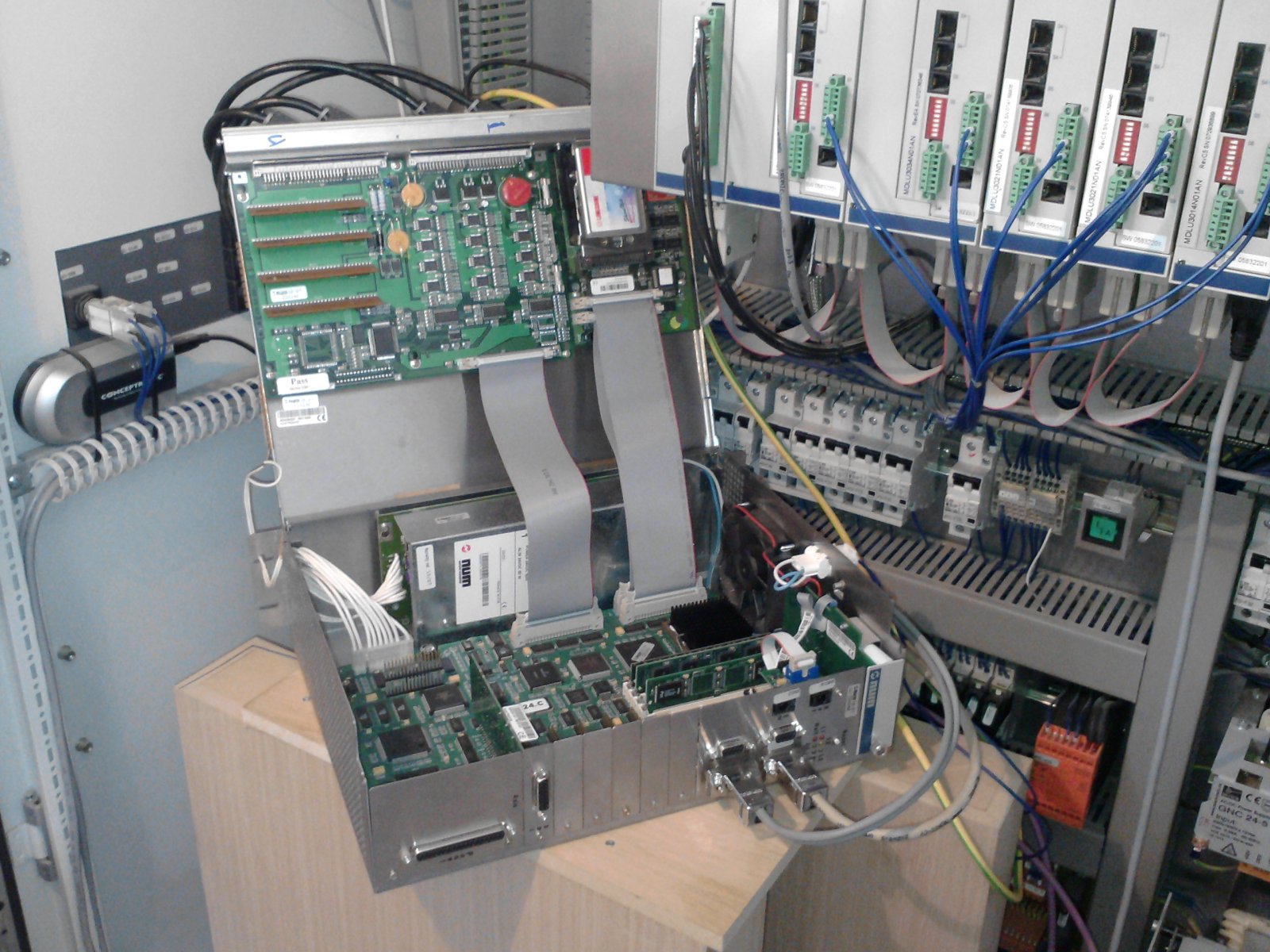

| The first module is on the surgery table |

It is very well made, after all, NUM is a top brand (and top-price) |

Be careful with the battery for bad things happen if it is unplugged |

Afterwards, we put it back into the cabinet and re-tested the machine. Guess what: the problem was still there. So we wear again our thinking cups... The customer said that the problem only occurs when the machine is in static mode, or when the power key is pressed, but never when the machine is in operation. A headache. We also tested the earth grounding cables, as i know that if the grounding of a machine is incorrect, crazy things happen. To be sure, we connected a new wire directly o factory's ground, yet the problem still occurred.

For some reason that i do not quite remember, while the machine was in operation, i tried to take the battery out of the controller. APOCALYPSE! The problem appeared as soon as i pulled the battery back! I instantly thought that the cables of the battery short-circuit the charging circuit, which causes the system to fail. I tried again and again to move the battery. Most of the times, the system failed. But strangely, no matter how hard i moved the wires (with the battery kept steady), the system did not fail. So, the cables of the batter were OK.

Another strange thing: Moving the battery outside the controller did not cause the problem. But moving it inside, the problem appeared. So i thought that the problem was on the charging PCB, because the battery was in direct contact with it. It was about time to take the controller on the surgery table again... This time, we checked and double checked the charging PCB for cold solder or other problems, but nothing suspicious could be found. So, we put the controller back in position again.

As always, i always slap-test electrical and electronic equipment. I call it "slap-test", whenever i slap slightly (or not so slightly) something to see if an error occurs. I did slap-test all the modules many times, but the problem did not occur. But something crazy happened: My colleague drove mad, and took the battery out and started moving nervously saying "you see? it is not the damn batter". And then, he left it on the controller with force! APOCALYPSE II: The error occurred when the battery touched the controller: Next logic though: The battery leaks to the controller chassis. So we connected a wire to the chassis, and started touching it on the battery... No problem at all. That was crazy...

And then, i slap-tested the controller again, not with my hand, but with a screwdriver. That's it! The error occurred every time i was hitting the controller with the screwdriver. Strangely, no matter how hard i was hitting it with my hand, it did not fail. But now i was sure that the problem comes from high-frequency vibrations. To discover exactly which connection was bad in the controller, we made a table inside the cabinet, and placed the controller on the table wide open, while the machine was still in operation:

And then, i tried hitting (slightly) the parts on the PCBs one by one with the screqdriver. APOCALYPSE III! The problem occurred when i hit the CPU! Actually, i only had to touch the CPU for the system to fail. It was obvious that the problem was on the CPU chip itself. Relief. So, again, we took the controller on the surgery table. This time, we took out the motherboard to check it for cold soldering or other problems. Again, the battery charger along with the battery had to be always connected on the motherboard. No problem was found in a first glance, so we took out the CPU, cleaned the base with spray, and put it back again:

|

|

|

|

| This time, we took out the motherboard from the chassis |

The CPU chip was removed from its base |

And

the base was cleaned with oil-less contact cleaner |

There was no thermal paste between the chip and the heatsink... |

|

|

|

|

| ... so we added some and put it back together |

We put the CPU back on the motherboard... |

...and test-run with the controller open... No problem at all !!! |

That's me testing the wires once more. |

Problem solved

So what really happened is this: When the machine is armed (when the operator presses the power button), two large load relays are armed simultaneously. These relays, cause high-frequency vibration on the back side of the cabinet, where the NUM controller is fixed, and this vibration caused the system failure. Most probably, a pin from the CPU had bad good contact with the CPU base.

So what we've learned from this? Slap test with the hand, and if nothing happens, use a screwdriver :D

Comments

At 1 January 2016, 11:53:49 user Claude wrote: [reply @ Claude]@Muhammad Faizan @Muhammad Faizan Hi Muhammad, It seems that the problem lies with the screw jack that lifts the arms. In my experience it's the brass gears that are worn. Try to see if the arms lift and lower without any problems in the manual movement page. You can also check that the contactor pulls in. The Y axis alarm could be because the tilting arms are not in position.

You can email me at claudez@wol.co.za

At 16 December 2015, 11:40:07 user Muhammad Faizan wrote: [reply @ Muhammad Faizan]Dear Sir,

I am Muhammad Faizan from the pakistan safety glass work karachi, pakistan the machine operator of CNC Bavelloni model"Rev 370 SLH"

Sir, i am facing a problem and the problem is that the FORK JACK is not working properly its going forword to pick the mirror but when the machine pich the mirror back to machine the jack stopped in the process of jack...software is asking for y axis drive not ready (trigger axes power not ready) so please kindly suggest the easy way to fix that problem.it will be very benificial for me...

At 9 October 2015, 20:18:58 user Claude Shunmugam wrote: [reply @ Claude Shunmugam]@CHRIS

Hi Chris. You need to firstly check all the output voltages from the power supply, eg: 0volt -0volt 5volt -5volt etc.

At 6 October 2015, 22:08:53 user CHRIS wrote: [reply @ CHRIS]I need help with a num 1040 controller. The problem started out when all three lights cam on at the same time. You reset the controller and it worked. Now only power light comes on and the controller canot be reset and does nothing.

At 4 April 2015, 4:29:25 user DNT wrote: [reply @ DNT]@ABE Hi,

Same to you, i have a trouble with my NUM 1040W. I think the backup battery is out of charge. Please show me how can i replace and reload program?

Thanks for your help.

At 4 April 2015, 3:29:08 user Ha Nguyen wrote: [reply @ Ha Nguyen]@Claude Shunmugam

Dir sir,

I have a trouble with our cutting machine (REV372).

I can%u2019t run software EASY CNC. The "Table Type Error" message appreas when i run this software.

I think battery in Cnc num 1040 had died, and lost all configuration parameter.

Could you please advise me for this trouble?

Kindly provide me your email address if possible.

My email is hantrev@gmail.com

Many thanks for your support.

Ha Nguyen from Vietnam.

At 12 March 2015, 9:22:15 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]

At 12 March 2015, 2:11:27 user Roger Casper wrote: [reply @ Roger Casper]sorry I forgot to include the link.

http://youtu.be/hKa3CVTC4MM

At 12 March 2015, 2:05:55 user Roger Casper wrote: [reply @ Roger Casper]good day sir,

Did you once before had this problem with a NUM 1040?

Dom Helder Camarastraat 113-115

1447 ZS Purmerend

Tel: 0299 475002

BTWNr.: 195867944B01

KVK: 37128694

E-mail: info@bgsens.nl

At 10 March 2015, 15:01:54 user ABE wrote: [reply @ ABE]I have a NUM 1040W control on morbidelli point to point machine, this controller goes to halt (red led light) 4-8 times per day, replaced the backup battery still doing the same, thank you.

Abe.

At 14 January 2015, 19:12:14 user Mladen wrote: [reply @ Mladen]Hi,

your site is full of interesting information,

I have one question,

with my CNC machine PLC is type%u010C NUM 1040, and it only the green LEDs indicates that there is power (24VDC). not that I had hoped monitor (I tried to put a new monitor). It also does not trigger the output relays, I think not include PLC, its operating system is not working.

I tried and retain 10 to restart, nothing happens.

Do you have a suggestion for what it is.

Thank you for your answers.

At 19 September 2014, 11:14:45 user MAJID wrote: [reply @ MAJID]hI

mY NUM CONTROLLER cOMMUNICATION MODUL FAIL YELLOW LED LITS AFTER A OFF AND ON OF THE MAINS .

HOW i MAY REMEDY IT ?

bEST rEGARDS

mAJID

At 6 September 2014, 11:29:48 user Claude Shunmugam wrote: [reply @ Claude Shunmugam]Hi, As a freelance technician for Bavelloni/Glaston glass processing machine', I have worked with Num controls and it's interesting to read some of these articles.

At 1 July 2014, 21:15:41 user Rick Noyola wrote: [reply @ Rick Noyola]hello I have a few stories on my own,today I have some issues with the battery, this was completely out of charge and now the memory when out I need you guys help. I need to reload the program back to our NUM 1040 unit.

Thank you for your help.

Ricardo Noyola.

Euroglas.mx

At 7 February 2014, 17:02:15 user mukesh wrote: [reply @ mukesh]Hi I have num750 cnc I did got lot of errror but I do my self repairs my process board setial port always burn what can I do I can't send program from pc if I did try nothing to receive in cnc please any buddy know about it help me.

At 19 April 2013, 17:19:11 user aluplastvz wrote: [reply @ aluplastvz]I have a problem my num 750 will accept the program with DNC communications when I try that after the information he then burst signal on the "?" gave some to them, and setup data

At 4 November 2012, 19:42:35 user demirhan bŁtŁner wrote: [reply @ demirhan bŁtŁner]i have a problem with vakkum.

At 28 September 2012, 13:01:15 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Kamaljeet sorry, dont know

At 28 September 2012, 12:44:28 user Kamaljeet wrote: [reply @ Kamaljeet]Sir,

I wants to know that which type of serial cable is used to connector PC with Bavelloni alpha 320 CNC Machine via com port

At 20 September 2012, 4:17:13 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Praveen Unfortunately i cannot help you with ll num controllers. I am CNC technician, not NUM specialist

At 20 September 2012, 2:48:48 user Praveen wrote: [reply @ Praveen]Hello

I have a problem in NUM 1040 ,since the machine was down for 6months unfortunately the battery is also dead,num lost the system data,

i did the transfer from PC to Nc to load parameters of the system through com port RS 232E.

I get a message slave not responding

1.Is there any other way to load the parameters.

2.Any drivers required to the num for the interface(Unitelway is already installed in the PC).

3.Could we change the com1 port to serial1(RS 485) to communicate .

4.Any hardware can be checked?

At 25 October 2011, 3:13:06 user john wrote: [reply @ john]Hi Aban

I have damaged of main board, there has come from oil leaking and hot temperature. how to solve the problem if come from hot temperature and oil leaking?

At 7 July 2011, 4:43:12 user Kammenos wrote: [reply @ Kammenos]@Aban i'm sorry Aban, but i am not a NUM controller specialist. I know how to load parameters and staff in a BIMA machine, but i am trained only for this current model. There has to be a special software that comes with the machine in order to do that. And either the software must run in the UI computer, or with an external computer through a special cable.

At 7 July 2011, 1:14:46 user Aban wrote: [reply @ Aban]Hi, Giorgos Lazaridis

Can u Help Me....for this.

I am in repairing Glass Cutting machine, Z Bavelloni S.P.A with cnc controller NUM, type 1040w , Serial No 136463, year 1999.

With trouble machine cannot start and all 3 axis cannot move..and previous the backup battery I have change it into new one.

for this machine system I am new I want ask you .

1. How to reload parameter. for Num 1040w controller.

2. Can you send for me manual for installation and setup this controller and the alarm list.

3. The display Alarm .1 , FHDL, and HOME Blinking.

4 How to Setup Parameter, Plc data & act for this controller.

5 What we do if backup battery lost voltage and after changge for new one.

Please help me.... and send the data to my Email : cncservis@yahoo.com

Thanks,

Best Regards,

Aban.

At 14 June 2011, 23:44:59 user charles wrote: [reply @ charles]Kammenos,

Hi all...i have read all the messages, as what you have talked to, we have also the same problem about the num memory...i would like to fix it but i need more idea to solve this problem..the error are this following:

program bigger than num memory

activete DNC mode

I'd press the OK button

after that another appears on the screen

file not found

and then i do press OK button again

another error appears

Bad file name or number...

this problem was starts when i load a big bytes of program...please help me and gain some ideas to solve this problem..

At 31 May 2011, 10:08:45 user Kammenos wrote: [reply @ Kammenos]@Clauds hi again. That is absolutely correct, you need to start with the classic automation first, to understand the relay logic. I suggest you study the "how relays work" theory page that i have first [http://pcbheaven.com/wikipages/How_Relays_Work/]. You may find interesting subjects there (it is 4 pages long). Also, it is absolutely essential that you learn how to read the electric diagrams of the machine. Then, you need to train yourself in reverse engineering. For example, if the motor fails to start, you locate the motor in the electrical drawing, and then you go backwards step by step, taking measurements in different points until you locate the error. Most of the times, the error is a defective relay contact or a loose wire.

Regarding the PCB manufacturing, i want to do some more tests. Yesterday i designed my first PCB with SMD devices and double-side. Before i make a tutorial for others, i want first to own the subject myself. It may take some time.

Oh, also, last week i retrofit an old bandsaw with a star-delta switch, and i added a star-delta motor automation. Within the next days i will upload this, as i have photos from the whole process. Subscribe to my RSS or twitter to get informed.

At 30 May 2011, 16:49:37 user clauds wrote: [reply @ clauds]Thanks for the quick response

Im interested in learning to repair the CNC's myself... but don't have any clue on where to start...

You say that I should learn automation and then progress from there?

I want to learn the problem solving and the specifics of CNC machines...

ps: when will you have the PCB making tutorial? I'm truly looking forward to that :)

Thanks

Clauds

At 30 May 2011, 9:36:34 user Kammenos wrote: [reply @ Kammenos]@clauds Hello Clauds. I am not sure that you want to learn about the electronics of a CNC, but rather about the electric installation. You want to know about problem solving or theory of operation? I cannot suggest you a book or site, because i learned myself the systems through the years of practice. The only books that i read so far are the datasheets of the parts (PLCs, inverters, controllers, drivers etc) and the electrical drawings. What i can surely suggest, are books about electrical automation. This will give you a kick-start to go to more advanced systems, like PLCs. You can experiment for example with the Mitsubishi Alpha PLC, which is powerful, easy to learn and relatively cheap.

At 30 May 2011, 5:39:01 user clauds wrote: [reply @ clauds]Hi Kammenos

Firstly, thanks for such a great and informative website, this is where i've learnt most of what I know now... However Im still a beginner in this field and have so much to learn, but 2 months ago I knew nothing about electronics and now can build systems that I can use...

Im a business owner with 45 CNC lathes, 12 CNC milling machines and 3 robotic arms...

Im creating my own terminal system for production monitoring and then plan to move over to creating robotics for CNC application...

I've designed quite a few things with the robots that the suppliers said was impossible, so im very keen to further my knowledge on my CNC machines because here in South Africa, we get charged an arm and a leg for repairs due the shortage of technicians and the crazy profits they want to make, and worst of all, they are not happy to try create new systems, they just want to make money from repairs...

Could you suggest any books or sites where I could learn more about the electronics for CNC machines?

Thanks

Clauds

At 25 April 2011, 21:16:30 user sessions wrote: [reply @ sessions]@Kammenos

Oh no, i am not a techician at all.

still a university student, electronics and computing engineering.

but since i am the only one in my fmaily with some knowledge of electronics i get all the no longer working electronics and i am expected to repair them. some do get repaired, many others end up worse than when i got them.

pardon my late answer i am not a regular.

At 13 April 2011, 4:40:49 user Kammenos wrote: [reply @ Kammenos]@Panagiotis that was a tough one. it took me like a day to find it. The nightmare in electronics is when the problem comes and goes.

At 12 April 2011, 21:17:13 user Panagiotis wrote: [reply @ Panagiotis]Wow amazing story!!!How many hours did it take to solve this problem???I had a quiet similar experience with a pcb of air-contioner....Electronics sometimes might make you crazy!!!!.

At 19 March 2011, 9:46:04 user Kammenos wrote: [reply @ Kammenos]hi sessions. Are you a CNC technician?

At 18 March 2011, 22:10:34 user sessions wrote: [reply @ sessions]Very interesting. Please continue updating with such stories. I tend to find problems like this one very frustrating. |

|

HOT in heaven! HOT in heaven!

|

|

Home

Home

Projects

Projects

Experiments

Experiments

Circuits

Circuits

Theory

Theory

BLOG

BLOG

PIC Tutorials

PIC Tutorials

Time for Science

Time for Science

Contact

Contact

Forum

Forum

Projects

Projects

Experiments

Experiments

Circuits

Circuits

Theory

Theory

BLOG

BLOG

PIC Tutorials

PIC Tutorials

Time for Science

Time for Science

RSS

RSS