PAGE 2 of 2

First of all, i had to fins a secure position for the circuit. This circuit will always have power, regardless if the CNC is turned on or off. So, it must be placed inside a separate electrical box for security reasons. The red LED will ensure that no-one will open this box without disconnecting the mains power from the CNC.

The best position is above the main switch for two reasons: First, there is enough place to fix the electrical box, and second because the wiring required will be minimal.

|

|

|

|

| This is the main switch |

I made 2 metallic plates and i screwed the electrical box on them |

This metallic plate will be fixed inside the electrical box |

The aluminum profile is a standard base for electrical equipment |

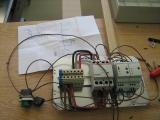

Wiring the components

|

|

|

|

| Never work without cable connector sleeves |

All parts are wired and fixed onto the metallic plate |

The plate along with the parts is screwed into the box |

The reset-button and the 2 LEDs are fixed onto the box cover |

The result

Well, it is not bad... I think i will use this method for other machines as well...

Comments

At 1 July 2013, 22:54:37 user Vince Geva wrote: [reply @ Vince Geva]Dear Giorgos,

We'd like to implement this idea of yours on our CNC machines pretty urgently. Where are you located, and can you be hired to do the job, or do you know of anyone who has repeated this process and made these devices for other CNC machine shops?

Thanks,

Vince |

|

HOT in heaven! HOT in heaven!

|

|

Home

Home

Projects

Projects

Experiments

Experiments

Circuits

Circuits

Theory

Theory

BLOG

BLOG

PIC Tutorials

PIC Tutorials

Time for Science

Time for Science

Contact

Contact

Forum

Forum

Projects

Projects

Experiments

Experiments

Circuits

Circuits

Theory

Theory

BLOG

BLOG

PIC Tutorials

PIC Tutorials

Time for Science

Time for Science

RSS

RSS