PAGE 2 of 2 - The DIS pin PWM control Advantages Disadvantages and Application Range

And what about the DIS pin?

There is still something that we haven't discussed about so far. In the previous schematic, there is one pin (pin 10) named DIS. This pin has dual operation. The name "DIS" comes from the "Disable/Enable". You may consider this pin as a switch. Leaving this pin unconnected, the SMPS does not operate and the LED is completely off. To turn on the LED, this pin must be connected directly to the ground. Here is a typical switch connection:

This pin can also be used to inject PWM pulses into the circuit and have brightness control over the LED. Be careful though, because you are NOT supposed to source any current into this pin. Instead you must sink this pin to the ground. There are several methods to do this. One very safe method is to add an external NPN transistor like this:

Now you can source PWM pulses of any magnitude above 3.5 volts from any sort of PWM generator, as long as the transistor T1 can handle the base voltage. The same transistor will sink the DIS pin to the ground. Use a fet transistor if you want to decrease the PWM amplitude below 3.5 volts.

Finally, you may use a circuit that does not source current, instead it sinks. One typical circuit is the PWM pulse generator shown in the LED driving and controlling methods in the page with the title "Injecting PWM pulses to control the brightness of the LEDs":

I use this circuit frequently, because of this very characteristic that it does not source current. Instead, i use the Pin 7 (Discharge) as an output which is connected to an internal open-collector transistor. You will need to couple the DIS pin to the Pin 7 of the 555 through a small limiting resistor of 1000 Ohms because the discharging transistor can handle up to some 55 mA of current. Here is a typical application circuit with PWM control using the 555 timer:

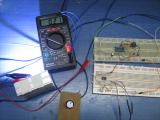

The supply for the 555 timer can be any voltage within the supply range of the chip (4.5V to 16V). The following pictures show this circuit in action:

|

|

|

|

| 30 mA |

210 mA |

550 mA |

max 960 mA |

Notice the potentiometer knob at the bottom of the pictures (white knob). The A6210 has a nice linear luminosity to duty cycle response. It worth to mention that if you provide PWM pulses directly to an LED to control its luminosity, the response will not be linear.

Advantages/Disadvantages

This chip has many advantages. First of all, it has a very small footprint (4 by 4mm QFN package). Additionally, the high frequency control allows the use of small inductors in size. Taking into account also that the output current ripple is very small and no output ripple capacitor is needed, and that only a few additional external components are needed, the chip can be mounted on a very small PCB board.

Regarding the efficiency, the A6210 performs very well. The manufacturer states that the typical efficiency is above 90%. Using the Design Tool provided by the manufacturer, the circuit that i designed has efficiency of around 93%.

The standby current when the DIS pin is unconnected is limited to 100 uA increasing therefore the power efficiency. The linear PWM control through the DIS pin adds flexibility in the design. The same chip can also be used for currents up to 3 amperes. The chip comes internal Thermal shutdown functionality to avoid overheating.

As for the disadvantages there are not really much to say. One major disadvantage is that the chip is not very widely used and therefore you cannot find it easily in all countries. Sometimes you will need to pay twice or more the normal price. Yet again, the chip is still considered as a cheap (cheap in price) solution and remains a good value for money.

One design problem that you will come across (like i did) is that the chip operates only as a buck converter which limits the application range. What this means is that the output voltage can only be less than the input voltage. If you plan to power a 12V LED for example, you will need a much higher supply voltage. I planned to make this circuit for a friend of mine to use it on his bike, but most bikes and cars (like his own) have one 12V battery, so it is not possible to operate, but this is typical in buck converters and should only be taken into account only as a note rather as a disadvantage.

Finally, a problem that i also came across is that the sense resistor is in the scale of milli-ohms. Taking into account also that the resistor is preferred to be SMD high precision, this can increase the cost unexpectedly. It was impossible for me to find a store in Greece with this type of resistors, so i had to use normal carbon resistor with 5% tolerance. This happens in high performance low quantity applications.

Application Range

This chip is a very good solution for high current applications, higher than 200mA and up to 3 amperes load. I suppose that in house and industrial applications it can work pretty well, since the supply voltage is not a problem - a 220/38V transformer will do just fine. Under these conditions, one chip can easily control an 80 Watts LED.

For automotive applications, it is important to remember that this is a buck converter, and that the LED span voltage must be less than the supply voltage. I would not consider using this chip for battery operated applications, flashlights and other similar low-voltage uses.

Comments

At 20 December 2013, 5:33:14 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]

At 19 December 2013, 22:33:57 user klemen wrote: [reply @ klemen]Hi I need to drive 11.5A, 10V laser diode.

Laser diode datasheet:

http://www.metalbot.org/forum/download/file.php?id=325

Can this be done with similar PCB?

Please leave me an email.

regards,

At 5 April 2013, 7:41:44 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@valquiria No, but you can find on ebay

At 4 April 2013, 23:50:08 user valquiria wrote: [reply @ valquiria]you have created or purchased qnf16 chip for A6210? You have the layout?

At 2 January 2013, 9:05:15 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@gustavo First of all, we have a forum for such long posts where others can participate. [http://www.pcbheaven.com/forum/]

I think that you've mistaken with the dis pin. Pulsing the dis pin will not pulse the output accordingly. The dis pin will change the valley current of the output (almost linear). You need to make a simple circuit first! Very important. Like, 12-24 volts voltage with one or two leds in series. Plus!!!! IF YOU have the circuit on breadboard, all your calculations are wrong. On breadboard you can only approximate values.

So, bottom line is: 1. Do not pulse dis pin for first circuit

2. Pulsing dis pin will NOT pulse the output. Do not expect any sort of PWM output

3. Dis pin controls the output current. 10% PWM at dis pin means 10% of the current selected

4. The output current will seem to you like mountains (that is why the chip operates as valley current driver). Looking thought the oscilloscope you expect to see an output voltage of something similar to triangular waveform, pulsing for a few hundreds of millivolts around your set value

At 23 December 2012, 13:44:53 user gustavo wrote: [reply @ gustavo]@Giorgos Lazaridis 2 things more:

I have conected nc pins to ground following datasheets schemes but i see you left these pins unconnected.

Also: R2 is not connected to pin number 9 directly, just to ground plane, and pin 9 also to ground. but they are sligtly far one from another

At 23 December 2012, 9:55:58 user Gustavo wrote: [reply @ Gustavo]@Giorgos Lazaridis Hi again.

I have tried to check what you suggest but something is happen. I'm confused abut the behaviour of my circuit.

I realized that I'm beeing a little boring: I'm trying to solve my own problem with the circuit, and this is a public forum so maybe this is nt the correct place to do it, so sorry about it.

I will try to explain what are the steps I have follow:

1.- My circuit is the one suggested by datasheet, whit values extracted from excel design tool. It means:

- Ten Leds in series

- First, I used next set of values R1:390k, R2: 75m, L1: 33uH. This means 2,6 A through the leds. Following leds datasheet, if I pulse the leds 100 us and let the leds off during some ms, the leds are capable to do that.

- But yesterday I thougth that I have to be more conservative, so I calculate the intensity for R1:390k, R2: 150m, L1: 33uH, which gives 1,3 A. This could be better in order to avoid leds burn. Also this give me, following leds datasheet about 1,7 -1,9 V in each leds. I have change R2 soldering another 75m in series.

- The input voltage is 40 V in the a6210.

- Dis signal is a pull down. When the transistor is on, Dis pin goes to GND for 100 us. When the transistor is off, I have no signal at all, and stays indeterminated theroetically, but with the osciloscope i can see it stays at 4 volts aprx. I think it is a normal behaviour, but I don't know if this is good for DIS pin.

- Well the first point that I think is not working well is that, disconnecting inductor from leds string (I have a jumper there), I have aprox 40 Volts when DIS is ON and then goes slowly down. I agree with yo that I can expect any special voltage as long as it is a current regulator and I do not have any load connected yet. But I expected, at least, a pwm voltage signal (with fast slow down, forming a square wave), despite there is no load. But what I have is a slow down curve when dis is on, so I have voltage on during 100 us , and a slowdown curve, that goes to Zero 1,5 ms after the pin dis is on. This is strange for me. But as long as this is a current regulator, maybe is a normal behaviour.

-So, going to your recomendations, I have connected the load connecting the jumper, and look with osciloscope what is happen. Maybe in this way I could check what happend in the led string and see voltage and intensity (with datashhet help). BUT, once I connect the jumper, signals (voltage output form the inductor and even DIS signal) goes realy noisy, with peaks of some volts(ten or more). Leds are obviously lighting very hot.

I'm really confused. The circuit is totaly correct. Maybe the values are incorrect or something, but i feel absolutly misplaced about this behaviour. Moreover, with this behavour I am not able to check any values or have a clue of what is happening

DO you have any ideas? Maye I can put some pictures of the oscilloscope but I dont know where

Sorry if you feel I am making and abuse of your help. It is not my intention

Thanks and best regards

At 22 December 2012, 20:55:01 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@gustavo you cannot read the voltage on a constant current device if there is no current to maintain constant... So you need the LEDs. OR a dummy load. Use an 1 Ohms high wattage resistor as dummy load for your tests. Measure the voltage across this resistor. Use ohms law to verify the results. Is the current a expected? For example, you want 2 amperes of current. So, there has to be a voltage of 2 volts across the resistor (and a lot of heat...).

At 22 December 2012, 20:47:41 user gustavo wrote: [reply @ gustavo]@Giorgos Lazaridis the time-dis on ( 0v to ground with a pull-down) is 100 us. the time for the dis off is 9ms. this is somethinthing i can not change

the intensity through the leds may be incorrect but it could be only because the voltage would be higher than 20v..i will check it.

In order to check it avoiding my leds burn out....if i check the voltage after tthe inductor output but without the leds connected..will i read correct values?

At 22 December 2012, 16:59:06 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Gustavo If you have the circuit always ON, is the current through the LEDs correct? Also, try higher frequency for DIS pin, like 1KHz

At 22 December 2012, 10:11:01 user Gustavo wrote: [reply @ Gustavo]I meaned 20 V in the led String

At 22 December 2012, 10:05:54 user Gustavo wrote: [reply @ Gustavo]@Giorgos Lazaridis Hi again:

I have finnaly made a pcb with the recommended design suggested by allegro, which is also your design (first picture in the post).

I have use more leds in series. My design have the next values:

R1:390k

R2: 75m

L1: 33uH

C1: 1uF

C2: 22nF

The circuit is designed to have 44 input volts, 40 volts led Span, and 2,7 A of current, BUT i will only turn on DIS pin 100us, with a frecuency not higher dozens of Hz. my Duty cycle is aprox 0.01

Well I have Cheched the systems, and it works BUT i have a very big problem: I am turning on DIS pin for 100 us, but the OUTPUT, the voltage wave that I obtain (and which is the final imput for the LED spam) have 100us high also, BUT a slow drop until 1 ms or more, which made it unable to work with, because in this way I'm over heating my leds, because they have a 10 times higher duty cycle that expected.

Do you know why this could be happen?

best regards

At 11 December 2012, 3:40:04 user Messiah wrote: [reply @ Messiah]@gustavo

Hi i did go through your circuit and it relates to my application needs. I want to drive LED string at 9V, 2A.

I can generate 12V on board.

My question is, what is the input supply current required by the IC?

At 10 November 2012, 19:18:11 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@luke chilson I just got a book "the art of electronics" but it is not for "starting". You may wanna start with a book from malvino. As for the chip, you wanna make an SMPS and drive the LED with an external mosfet.

At 8 November 2012, 2:41:34 user luke chilson wrote: [reply @ luke chilson]hello and first id like to say thank u for all of the good info you do it great im just starting in electronics can u recommend any good book to read from very basics to advanced also could u recommend a chip that can drive an led (SST90 LED) at 9 amps or 8 thank u very much luke

At 28 October 2012, 9:06:02 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@gustavo Alegro clearly states 44V max - above that may degrade or destroy the chip. As fro the voltage drop, do not calculate the power dissipation as you do with linear regulators. This is a buck regulator. You can drop 40V down to 3V 1A without any problem. The only heat that will be generated is from I2R loses. Check out the attached document in this page - the excel sheet.

- you will calculate the excel for max intensity. Tracks must be able to provide the required current. As for the calculations, they are of course related to the luminosity (current)

- Hmmm good question. First of all, make sure that all NC and GND pins as well as the central PAD have enough copper around to act as a heatsink. The high current provided by the chip is on a corner pad, so you can use a thicker wire as an extend of this pad. I am not sure if this is needed though.

-The chip has voltage reference down to 180 mVolts, so a current of 750mA for instance will dissipate some 135 mWatts. Again, this is not a linear regulator, it is a buck regulator.

At 23 October 2012, 13:10:47 user gustavo wrote: [reply @ gustavo]@Giorgos Lazaridis

Thanks for your response. I have been going further in my design. I have seen that, at least in theory, I can power my allegro with 48V. So I wont need to drop the voltage. Am I right? And, if I do that, I will input 48 Vin, but at the same time I will output 20 Volt. It's the allegro capable of do that? How can I deal with the chip so my chip does not burn?

I have some more questions

-I will need 2.5 A, BUT, I will do a PWM cycle of 1ms on - 19 ms disabled. Should I do calculations in excel with total Intensity or with Average intensity?. Moeover, does this affect my calculation (excel calculation)? and my practical circuit design ( circuit tracs, pads, etc. ?)

-I guess I also need wide tracks and nets in my circuits, and also copper. BUT, pins in allegro are really thiny. How could I deal with that?

- I have seen your design, and, my dout is: Which is the intensity trhough the resistors part? why you use so low-power resistors (1/4 W)?

At 21 October 2012, 8:19:17 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Gustavo -from 48 to 44 volts, or down to 42 volts for safety, means that you need to drop 6 volts. At 3 amperes, this means 3x6=18 watts. This is really a LOT of power drop. You will need 3 resistors of 10 Watts each connected in series to split the enormous heat.

-Of course you can power the chip with less voltage. Check out the attached excel sheet - there is a specific limit of lower voltage that you can go to. The lower the voltage you choose, the lower the switching frequency. As for the heat, make sure that you use 2-sided PCB, one side of which is copper heatsink for the chip, coupled with vias from the middle pad (check datasheet)

-Although i have never test this, i'm pretty sure that you can achieve this with a transistor. I do not think that you can find a variable resistor suitable for this application. BUT - BUT - The a6210 has a PWM input which does exactly this... It works very well and has pretty much linear response to the PWM duty cycle. So better follow the PWM solution which can dim the LEDs from 0 to 100%

At 18 October 2012, 11:20:25 user Gustavo wrote: [reply @ Gustavo]Very nice site Giorgios:

I am trying to design a power stage in a PCB that will supply high power leds, Ir leds dragon from osram. My PCB is supplied with a 48V estandard power source from meanwell

I will pulse the leds in order to have much more efficiency and radiant flux. What I'm calculating is to have about 2.5 A and probably 1.7-1.8 V in each led. Probably i will put a string of 8-10 leds, which it means that I will need between 15V or 20 Volt in the Ic output. My questions are:

- As long as I have read, I could supply the allegro IC to almost 48 V(46V), so probably I will need to step down a little my voltage, probably with a resistor voltage divider. But (see my next question) If the chip can drive up to 3 A I am not sure that my voltage divider resistor could not burn out.

- Can I input the chip with, lets say 40 V , and output it with lets, say 20 V and 2.5 A? Whats happens with the temperature management? I guess that, if I need to suplly 2.5A, I will need good disipation in the chip. Of course, I will not supply 2.5 A in cc, but i will supply it with probably 0.1 duty cicle

- If I'd like to manage and change the output current, can I put a variable resistor in order to supply the needed current? can you figure out how to control the current with a micropic pin, for example?

best regards

At 23 July 2012, 19:45:31 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Stavros G First of all, 24 V may not be enough and the switching frequency will be very very low. I suggest that you make some theoretical tests with the excell sheet i provide and go for higher voltage. With your questions:

1) no i have not seen one. This chip is not very popular.

2) i tried a setup with 6 leds 3.7V each at 750mA with supply 42 volts and the fluctuation was 2 volts maximum with 2 large capacitors (4700 and 1000)

3)for which cap are you talking about? The cboot cap should be ceramic. The supply cap can only be electrolytic, because it needs a lot of uF

BTW: Soldering this chip on a breadboard will be a nightmare without the proper tools and some experience, and it may also be a reason for failure.

At 21 July 2012, 18:35:46 user Stavros G wrote: [reply @ Stavros G]@Giorgos Lazaridis Hey there! It's me again! So, as I have already told you I'm working on a Led luminaire for my diploma thesis.

I have been given the OK from the lab to construct a small scale prototype in order to experiment and take all the necessary measurements for the needs of my thesis. They have given me a prototype board with six LEDs in series to experiment with. Whatever I come up with, can be further generalized for a larger scale luminaire.

So, I will be using this configuration to drive the LEDs with 800mA ,which means a 3.5V forward voltage across each LED and thus a total LED span voltage of 21V. My source will be a 24V battery whose voltage i will step down to 21V using the A6210. I will then feed PWM to the DIS pin through an Arduino in order to easily experiment with the control of LEDs' brightness.

A few quick questions:

1)Do you know if there is a model of the A6210 to use with a simulation software (Orcad Pspice, matlab/simulink etc)?

2)In your experience, how much does the fluctuation of the input voltage affect the output voltage?I am asking because I will be using a battery as a source...

3)Does it make any difference if I use ceramic or electrolytic capacitors?

I think the safest way to go is start with a breadboard and maybe later move to a pcb. So at least for now I am stuck with 5% tolerance resistors right?

One major concern I have is how am I gonna solder the QFN to the DIP adaptor since i am not experienced in soldering SMD components :-/

At 19 June 2012, 22:05:31 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Walt I'm just trying to do my best and work it out through the recession ;)

At 19 June 2012, 20:39:15 user Walt wrote: [reply @ Walt]Very nice website Giorgos. This was an article that was useful to me as I am trying to build a led driver for my personal use without having to buy ready made. I've just started exploring your website. Looks like many good things are here. I hope your are doing well in your local area.

At 5 June 2012, 15:01:42 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Stavros G I managed to make a circuit to control 20W LEDs from full bright (750mA) to full dimmed (pulsing), and the circuit dissipated less than 1 watt. This was achieved only by increasing the voltage.

As for your question, you can make 2 branches, each one providing 3 amperes. It is not wise to connect LEDs in parallel because a slight difference could unbalance the parallel branches. Should you wish to connect LEDs in parallel you need to consider using balancing resistors in series with each parallel branch. That is very important.

At 5 June 2012, 14:40:20 user Stavros G wrote: [reply @ Stavros G]@Giorgos Lazaridis The datasheet says the a6210 chip can handle up to 3A. So what if I use two a6210 chips, each one in the configuration you present in this post, and then connect the two circuits in parallel (connect the two Lx pins to one common node which will then drive the load)? Would something like that be possible or am I being stupid? :-P

I will have to do some calculations some research on the characteristics of the battery i will be using and come back to you with the numbers...

I will try to rearrange the LEDs to decrease the current and increase the voltage.

At 5 June 2012, 10:49:58 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Stavros G Hello Stavro. 6A are way too much for this chip. Tell me your configuration, number of LEDs, current and voltage. Maybe you can increase the voltage and decrease the current. What is the total power? The A6210 can easily handle some 60 Watts and in some situation more.

I have not work yet with boost configurations, so i cannot have a good opinion about boost chips. But the current that you require to provide is too much.

Something else: How are you supposed to power those LEDs? With battery or mains power (220)?

As for the problem, there will be problems of course in high switching signals. The resistor values that you will come up with will not be accurate. Breadboards have huge parasitic capacitance between the connectors, so it is good only for tests. For prototyping you'd better consider making a PCB.

At 5 June 2012, 8:14:44 user Stavros G wrote: [reply @ Stavros G]Hello there!

First of all I would like to congratulate you guys for the excellent work you have been doing!The tutorials, the videos, the projects, the theory pages, everything is great and really comprehensive!So bravo!

I have been working on a stand alone outdoor LED luminaire project for the last few weeks and and i've been looking for a driver that is configurable, easy to implement , features PWM and has sufficient documentation for quite a while. This post helped a lot!

In my application I will need to supply the LEDs with about 6A. So I was wondering, how would you do that?

Would a parallel connection ,of two identical circuits as the one presented above, be an appropriate solution?

Also, just in case, have you found a similar chip that can be configured as a boost dc/dc?

P.S. Am I going to have noise problems if i test this on a breadboard?

At 25 April 2012, 12:22:03 user Giorgos Lazaridis wrote: [reply @ Giorgos Lazaridis]@Abdullah Kahraman certainly not a good idea. I have already make a pcb, and i am about to make another one for my kitchen lights. I will publish that one when it is ready for 10x1W led controller.

At 25 April 2012, 6:36:10 user Abdullah Kahraman wrote: [reply @ Abdullah Kahraman]Hi, great review of the chip. However, it's really not a good idea to breadboard switchers that works over 200KHz :)

Are you going to design a PCB for this project? |

|

HOT in heaven! HOT in heaven!

|

|

Home

Home

Projects

Projects

Experiments

Experiments

Circuits

Circuits

Theory

Theory

BLOG

BLOG

PIC Tutorials

PIC Tutorials

Time for Science

Time for Science

Contact

Contact

Forum

Forum

Projects

Projects

Experiments

Experiments

Circuits

Circuits

Theory

Theory

BLOG

BLOG

PIC Tutorials

PIC Tutorials

Time for Science

Time for Science

RSS

RSS